What does uhmw stand for?

Acronyms and abbreviations abound in the field of materials science. One of the acronyms that may pique your curiosity is "UHMW". If you're wondering what UHMW stands for and why it's so important, you've come to the right place. UHMW stands for ultra-high molecular weight polyethylene, a remarkable material with a wide range of applications. In this article, we'll explore the world of UHMW, its properties and its many uses in a variety of industries.

Understanding UHMW: What is it?

UHMW, which stands for ultra-high molecular weight polyethylene, is a polyethylene plastic that is characterised by its extremely high molecular weight. To understand what makes UHMW unique, let's break down the acronym:

Ultra-High Molecular Weight (UHMW): The term "ultra-high molecular weight" refers to the size of the polymer chains in a material. In UHMW polyethylene, these chains are very long and consist of thousands to millions of repeating ethylene units. This high molecular weight gives the material a number of remarkable properties.

Polyethylene: UHMW is a type of polyethylene and is a widely used polymer. Known for its versatility, polyethylene is available in a variety of forms such as Low Density Polyethylene (LDPE), High Density Polyethylene (HDPE), and Ultra High Molecular Weight Polyethylene, each with unique properties.

Properties of UHMW

UHMW polyethylene has a number of outstanding properties that set it apart from other materials:

Superior abrasion resistance: UHMW is known for its excellent abrasion resistance, making it ideal for components that come into contact with abrasive materials. It is commonly used as a liner or coating for chutes, hoppers and conveying systems in industries such as mining and agriculture.

Low Coefficient of Friction: UHMW has a low coefficient of friction, similar to PTFE (Teflon). This characteristic reduces the need for lubrication in applications involving sliding or moving parts, resulting in reduced maintenance and longer part life.

High Impact Strength: Despite its low density, UHMW has high impact strength, making it tough and durable. It absorbs and dissipates impact energy without breaking or cracking, making it suitable for applications where impact resistance is critical.

Chemical Resistance: UHMW is highly resistant to a wide range of chemicals, including acids, bases and many solvents. This property makes it suitable for use in chemical processing equipment and environments where corrosive substances are present.

Low Hygroscopicity: UHMW has low hygroscopicity, meaning it is less likely to absorb water. This property makes it an excellent choice for applications that require moisture resistance, such as marine components or food processing equipment.

Excellent dielectric properties: UHMW is an excellent electrical insulator, making it suitable for electrical and electronic applications. It is non-conductive and can be used in electrical insulators, sleeves and other components.

Biocompatibility: UHMW is considered biocompatible and is used in medical and healthcare applications, including orthopedic implants and prosthetics.

UHMW applications

The exceptional properties of UHMW polyethylene make it a versatile material with a wide range of applications in a variety of industries:

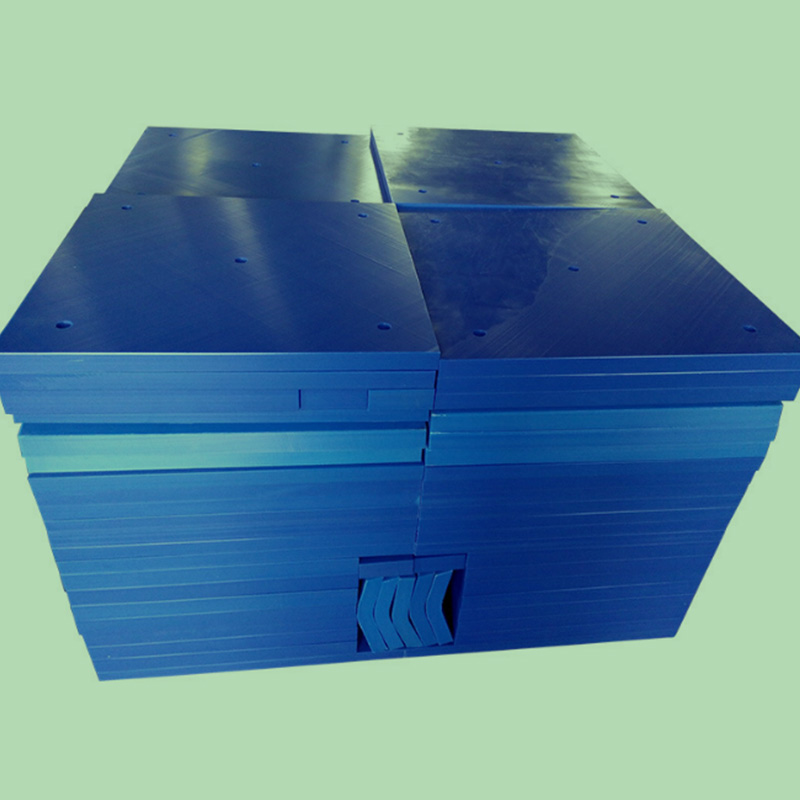

Material Handling: UHMW is commonly used as a liner for hoppers, chutes and conveyor systems in industries such as mining, agriculture and bulk material handling. Its low friction properties reduce material build-up and increase efficiency.

Bearings and Bushings: Because of its low friction and excellent wear resistance, UHMW is used to make bearings, bushings and other sliding parts in machinery and equipment.

Food processing: UHMW is FDA-compliant and safe for use in food processing and packaging equipment. It is used in conveyor belts, cutting boards and other food-grade applications.

Medical Devices: UHMW is used in the manufacture of medical devices, including orthopedic implants, joint prostheses and surgical instrument components.

Automotive: UHMW is used in the automotive industry for components such as gears, bushings and chassis protectors due to its durability and low friction.

Marine and Offshore: UHMW's moisture and corrosion resistance makes it suitable for marine applications, including ship fenders, dock bumpers and underwater components.

Electrical and Electronics: UHMW is used in electrical insulators, cable conduit and insulation sleeves due to its excellent dielectric properties.

Sporting Goods: Due to its toughness and low friction, it is used in the manufacture of sports equipment such as skateboard ramps, ski bases and kayak hulls.

Conclusion

UHMW, which stands for ultra-high molecular weight polyethylene, is a material with exceptional properties that can be used in a wide range of industries. Its exceptional wear resistance, low friction and chemical resistance make it a valuable choice for components and applications where durability and reliability are critical. From material handling and medical equipment to automotive and marine applications, UHMW has proven its ability to serve as an indispensable and versatile material for the modern world. So the next time you encounter a smooth, durable surface or low-friction component, you may appreciate the wonders of UHMW.

Comments

0