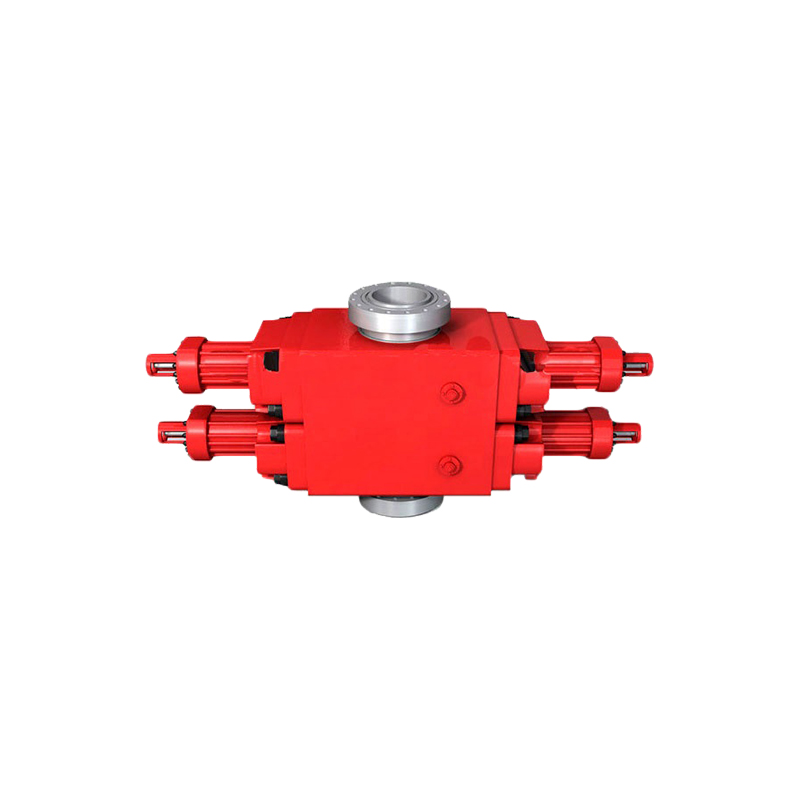

Enhancing Oilfield Safety with Sucker Rod Blowout Preventers (BOPs) for High-Pressure Environments

In the dynamic and demanding world of oil and gas extraction, safety is paramount. When dealing with high-pressure operations, the role of effective equipment becomes even more critical. Sucker Rod Blowout Preventers (BOPs) stand as stalwart guardians, ensuring the well-being of personnel, the integrity of equipment, and the protection of the environment. In this comprehensive guide, we delve into the intricacies of Sucker Rod BOPs and their indispensable contribution to oilfield operations.

Understanding the Essence of Sucker Rod BOPs

The Crucial Shield Against Catastrophic Blowouts

High-pressure environments within oilfields pose significant challenges. A blowout, characterized by an uncontrolled release of oil or gas, can lead to disastrous consequences, endangering lives, causing extensive damage, and resulting in environmental havoc. Sucker Rod BOPs play a pivotal role in averting such catastrophic events, providing a reliable and robust barrier that prevents the uncontrolled flow of fluids from the well.

Tailored Engineering for Harsh Conditions

Oilfields can be harsh and unforgiving, subjecting equipment to extreme pressures and conditions. Sucker Rod BOPs are engineered with precision to withstand these challenges. Constructed from high-strength materials and equipped with advanced sealing mechanisms, these BOPs function seamlessly under duress, assuring uninterrupted protection against blowouts.

Unveiling the Features of Sucker Rod BOPs

1. Hydraulic Control System

At the heart of every Sucker Rod BOP lies a sophisticated hydraulic control system. This system empowers operators with precise control over the BOP's functions, allowing for rapid responses to changing conditions. Whether it's activating the BOP to seal the well or disengaging it during routine operations, the hydraulic control system ensures seamless and efficient functionality.

2. Robust Sealing Mechanisms

Sucker Rod BOPs are equipped with multiple layers of robust sealing mechanisms. These mechanisms, often comprising elastomers and metal-to-metal seals, provide a reliable barrier against the uncontrolled release of fluids. Even in the face of extreme pressures and temperatures, these seals maintain their integrity, reinforcing the safety of the operation.

Recommended article:Which industries benefit the most from Precision Investment Casting technology?

What is a Double Eccentric Butterfly Valve used for?

Pros And Cons Of Thermoset Injection Molding

Troubleshooting Slurry Pump Issues: When and How to Replace Parts

What are the common types of bearings used in electric motors?

How many years do bellow seal valves last?

Globe Valve vs. Gate Valve

3. Redundancy for Unwavering Reliability

In critical operations, redundancy is a non-negotiable requirement. Sucker Rod BOPs are designed with redundancy in mind, featuring multiple sealing layers and control systems. This ensures that even in the event of a component failure, the BOP remains operational, offering unwavering reliability and safeguarding against blowouts.

The Unrivaled Advantages of Sucker Rod BOPs

1. Personnel Safety

The foremost advantage of Sucker Rod BOPs is the protection they afford to personnel. By preventing blowouts, these BOPs mitigate the risk of life-threatening incidents, creating a secure working environment for oilfield operators and technicians. This commitment to safety is a testament to the industry's dedication to its workforce.

2. Equipment Preservation

Blowouts not only endanger lives but also jeopardize valuable equipment. Sucker Rod BOPs act as stalwart defenders of equipment integrity, preventing potential damage caused by uncontrolled releases. By safeguarding the longevity of equipment, these BOPs contribute to cost savings and operational efficiency.

3. Environmental Stewardship

The impact of a blowout on the environment can be devastating. Sucker Rod BOPs assume the role of environmental stewards, ensuring that oil and gas extraction operations remain contained and controlled. This proactive approach minimizes the risk of ecological damage and aligns with responsible industry practices. click here

Conclusion

In the fast-paced and high-pressure realm of oil and gas extraction, Sucker Rod Blowout Preventers emerge as indispensable sentinels of safety and efficiency. Their hydraulic control systems, robust sealing mechanisms, and unwavering reliability position them as paramount tools in the arsenal of any oilfield operation. By investing in Sucker Rod BOPs, companies demonstrate their commitment to safety, equipment preservation, and environmental responsibility.

As the industry evolves and embraces technological advancements, Sucker Rod BOPs stand strong as a testament to innovation and progress. They are not just pieces of equipment; they are guardians of well-being, champions of sustainability, and pillars of success in the dynamic world of oilfield operations.

Recommended article:How does a Dredger Pump Work?

What are the benefits of low pressure molding?

Differences Between Pipe Joints And Pipe Fittings

Comparing Grey Iron Casting with Other Casting Methods: Benefits and Limitations

What are bevel gears used for?

What are the advantages of ball valves?

What are Major Functions of an I/O Module?

Related Articles

-

Weir Type Diaphragm Valve: A Reliable Solution for Flow Control

432

0

0

-

The Advantages of Overhead Conveyor Bearings in Industrial Automation

-

Drum Gear Coupling: The Backbone of Efficient Power Transmission

-

Steel Braided Hydraulic Hose: The Strong and Reliable Solution

397

0

0

-

Choosing the Right Diesel Engine for Your Vehicle or Equipment

424

0

0

Comments

0