FRP grating has five advantages over traditional grating

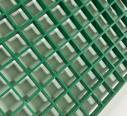

FRP grating is a plate-like material with a large number of spaces, which is made of glass fiber as a reinforcing material and unsaturated polyester resin as a base material. It is a combination of special processing technology and has excellent properties such as light weight, high strength, corrosion resistance, flame retardancy, and anti-skid. It is mainly used in industrial fields such as ground, trench covers, platforms, and ship decks. However, since FRP grating plays an irreplaceable role in people's lives, manufacturers of FRP grating can be seen almost everywhere.

Continuous fiber winding process (continuous method): This process uses a core mold to continuously convey a roving forward, and the resin is added once to immerse the twisted roving, and the feeding device of the chopped glass fiber and resin sand mixture.

Ordinary gratings are prone to aging and rusting, have low strength grades, and are not easy to resist atmospheric and acid-base corrosion. FRP grating can well solve the shortcomings of traditional grating plates, and the price is moderate. It is a substitute for old steel gratings, plastic gratings, and metal gratings.

FRP is a composite of resin and glass fiber. Its density is relatively low. Compared with steel grid, FRP grid is only 1/4 of steel and 2/3 of aluminum. Its strength is 10 times that of rigid polyvinyl chloride, which is higher than aluminum and reaches the level of ordinary steel. It has a light weight, which can greatly reduce the foundation support and reduce the project cost. It is simple to cut and install, does not require fire and large lifting equipment, and only requires a small amount of manpower and power tools, so the installation cost is also greatly reduced.

High-quality FRP grid products have no obvious cracks on the appearance, few pores, pure color, good transparency, certain toughness, high strength, smooth surface and long service life; while inferior FRP grid products have cracks on the appearance, more pores, impure color and insufficient gloss. Its life is also relatively short.

Fiberglass grid plate has received 68% unanimous praise in the industry and can cope with the above results. With the emergence of more tree comb consumers, more and more forms of cooperation have emerged. His density is not as high as other parts of the tree comb, but it does not help growth. Good tolerance. FRP is a grid-shaped hollow material that does not require protection: it is relatively reluctant in the field of corrosion protection, and through the use of beautification design, it can better resist the erosion of rain and snow.

The FRP grating material is made of resin, FRP fiber, and calcium filler in a 1:1:1 ratio. High-quality FRP gratings use high-quality resin: 196 unsaturated phthalic resin, colorless and transparent. Low viscosity, low heat release, low shrinkage, high-speed curing, high-speed compatibility, and bright gloss. The product has the characteristics of smoothness, smoothness, good gloss, high strength, and certain toughness. If inferior resin is used, it will be completely the opposite. Inferior resin will be turbid, high viscosity, high heat release, large shrinkage, relatively slow curing, poor compatibility, and the produced FRP grating will be porous, easy to break, and have poor strength.

Reciprocating winding method (fixed length method): In this process method, the dipping tank and the rotating mandrel make reciprocating motion together; when the mandrel shaft is placed, the long fiber glass fiber has a certain inclination angle, and the winding angle (i.e. the winding angle) is controlled by the ratio of the movement speed of the dipping tank and the rotation speed of the mandrel, and the translational movement of the dipping tank is controlled by a computer. The number of winding layers gradually increases until the design requirements are met. After the winding is completed, the resin is basically solidified in the product. After vulcanization, the mandrel is removed from the FRP tube.

The raw materials of FRP mesh are resin, glass fiber and calcium powder filled in a ratio of 1:1. High-quality FRP mesh is made of high-quality resin: 196 unsaturated phthalic resin, colorless and transparent. Low viscosity, low heat release, low shrinkage, high-speed curing, high-speed compatibility, gloss. The product mesh surface is flat, smooth, bright, high-strength and has a certain toughness. If inferior resin is used, the situation will be completely opposite. Inferior resin is turbid, high viscosity, high heat release, high shrinkage, slow vulcanization and poor compatibility. The obtained fiberglass mesh holes are easy to break and have low strength.

Comments

0