How does a turret CNC lathe machine work?

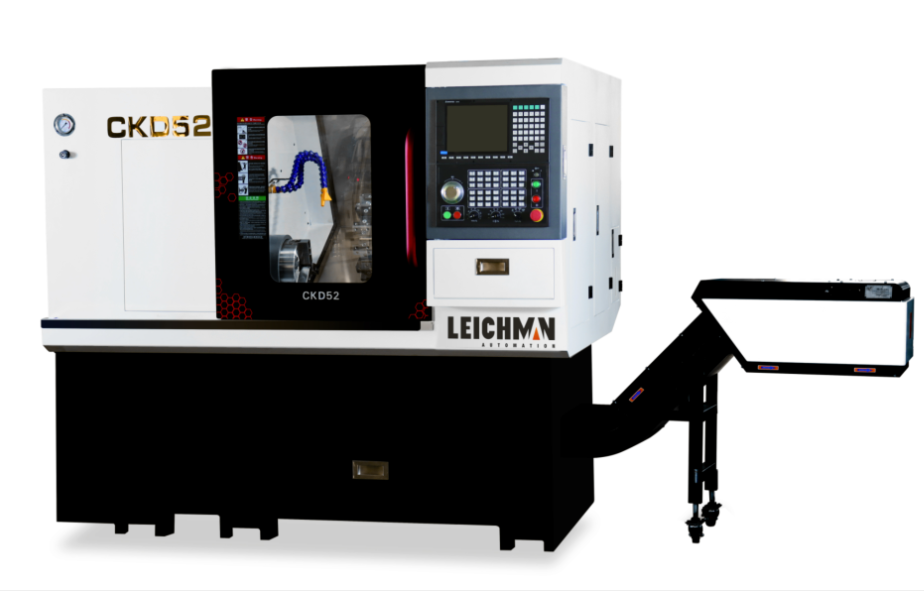

A turret CNC lathe is a computer-controlled machining tool designed for the precise and efficient turning of workpieces. It is a critical asset in the manufacturing industry, offering unparalleled accuracy and versatility. Let's break down the various components and processes that make these machines stand out.

Components of a Turret CNC Lathe Machine

1. The Bed and Base

The foundation of any Leichman CNC lathe machine is its robust bed and base. These components provide stability and support for the entire machine. Typically made of high-quality cast iron, the bed and base ensure minimal vibrations during operation, which is crucial for achieving precise machining.

2. Headstock

The headstock houses the spindle, which rotates the workpiece. It plays a pivotal role in determining the speed and power required for different machining tasks. The headstock can be adjusted to accommodate workpieces of varying sizes and materials.

3. Turret

The turret is a versatile tool holder that carries various cutting tools. It can rotate and index automatically, allowing for rapid tool changes during the machining process. This feature is essential for producing complex and intricate parts efficiently.

4. Guideways

Precision and smooth movement are the keys to high-quality machining. Turret CNC lathe machines utilize linear guideways to guide the cutting tool's movement, ensuring accuracy and repeatability in every operation.

5. Control Panel

The brain behind the entire operation, the control panel is where the magic happens. Skilled operators input the necessary commands and parameters, allowing the CNC system to control the machine's movements with unparalleled precision.

How a Turret CNC Lathe Machine Operates

Now that we've explored the components, let's dive into how a turret CNC lathe machine operates, step by step.

1. Workpiece Preparation

The process begins with preparing the workpiece, securing it in the chuck or collet of the machine's spindle. Proper alignment is essential to ensure precise machining.

2. Tool Selection

The operator selects the appropriate cutting tools and loads them into the turret. Each tool serves a specific purpose, and their selection depends on the machining requirements.

3. Programming

Once the workpiece and tools are ready, the operator creates a program that outlines the machining process. This program includes details such as spindle speed, feed rate, toolpath, and tool changes.

4. Machining

With the program in place, the CNC system takes control. The spindle begins to rotate, and the turret indexes to the selected tool. As the workpiece spins, the cutting tools come into contact with it, removing material with precision.

5. Continuous Monitoring

During the machining process, the CNC system continuously monitors various parameters, making real-time adjustments to ensure accuracy and quality. This level of automation minimizes human error and enhances efficiency.

6. Completion

Once the machining process is complete, the turret CNC lathe machine delivers a finished workpiece that meets the exact specifications outlined in the program.

Advantages of Turret CNC Lathe Machines

CNC lathe machines offer numerous advantages in the world of manufacturing:

Precision

These machines can achieve exceptionally tight tolerances, ensuring that every part produced meets the desired specifications.

Efficiency

The ability to automate tool changes and other processes increases production efficiency, reducing manufacturing time and costs.

Versatility

Turret CNC lathe machines can handle a wide range of materials, making them suitable for diverse machining tasks.

Quality

The consistency and accuracy of CNC machining result in high-quality parts and components.

In the realm of precision manufacturing, the turret CNC lathe machine reigns supreme. Its intricate components and advanced automation make it an indispensable tool in industries that demand accuracy and efficiency. By understanding how these machines work, you gain insight into the marvel of modern engineering that drives countless manufacturing processes.

Comments

0