What Are Oil Seal Kits Used For?

In the vast and intricate world of machinery, where components work in tandem to achieve precision and efficiency, maintaining the integrity of moving parts is of paramount importance. One often overlooked yet critical aspect of this maintenance is the use of oil seals. These unassuming components play a vital role in ensuring the smooth operation and longevity of various mechanical systems. In this article, we will delve into the world of oil seal kits, understanding their purpose, applications, and significance in machinery maintenance.

The Role of Oil Seals:

Before delving into the specifics of oil seal kits, it's essential to grasp the fundamental role of oil seals themselves. Also known as shaft seals or rotary seals, oil seals are designed to prevent the leakage of fluids and the entry of contaminants in mechanical systems. These systems encompass a broad range of applications, from engines and gearboxes to pumps and industrial machinery. The primary function of an oil seal is to create a barrier that prevents lubricants, hydraulic fluids, and other essential fluids from escaping while blocking dirt, dust, and moisture from infiltrating the machinery.

Oil seals achieve this through a combination of design elements. Most commonly, an oil seal consists of a flexible sealing lip that makes contact with the rotating or reciprocating shaft. This lip is typically made from a rubber or elastomeric material that provides a tight seal against the shaft's surface. The housing or case of the oil seal is installed securely in a stationary component, such as the housing of a gearbox or the casing of an engine. This arrangement ensures that the seal remains in place while allowing the shaft to rotate or move freely within the seal's lip.

Understanding Oil Seal Kits:

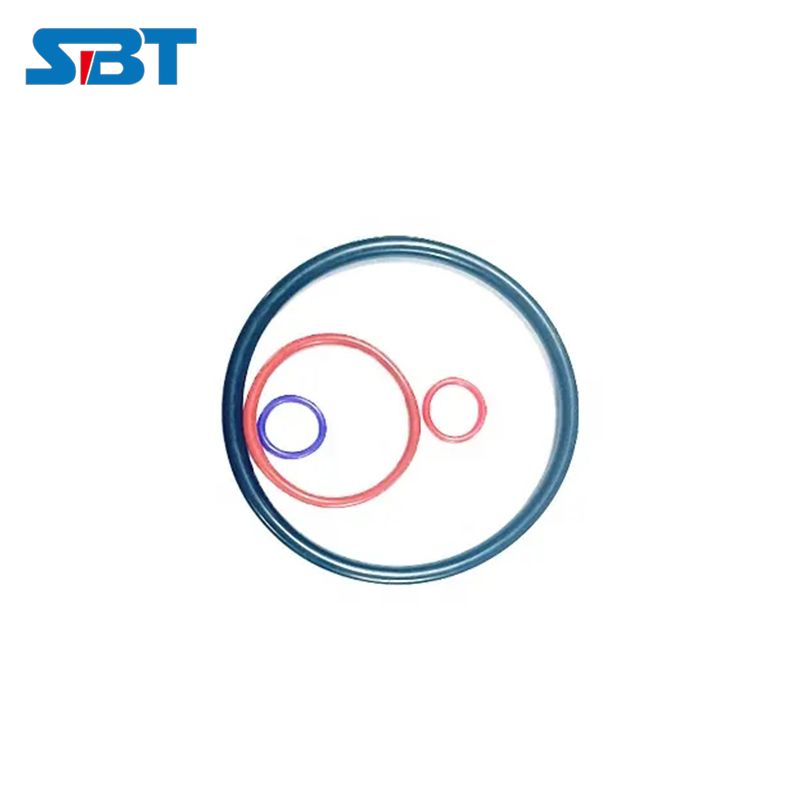

Now that we've established the importance of oil seals, let's delve into the concept of oil seal kits. An oil seal kit is a comprehensive package that includes all the necessary components for replacing or installing an oil seal. These kits are designed to simplify the maintenance process by providing mechanics, technicians, and equipment owners with everything they need in one convenient package. An average oil seal kit includes the oil seal itself, any necessary gaskets or O-rings, and potentially other components required for the installation.

Oil seal kits serve as a time-saving solution for maintenance tasks. Rather than searching for individual components and risking mismatched parts or incomplete installations, technicians can rely on oil seal kits to contain all the components required for a seamless replacement process. This ensures not only the correct fit and performance of the new oil seal but also reduces the risk of leaks and failures caused by improper installation.

Applications of Oil Seal Kits:

The applications of oil seal kits are vast and varied, as they are essential in a wide range of industries and mechanical systems. Here are a few key areas where oil seal kits find extensive use:

Automotive Industry:

In automobiles, oil seal kits are crucial for maintaining the performance and efficiency of engines, transmissions, and differentials. They prevent oil leaks that could lead to lubricant loss and mechanical damage, ultimately affecting the vehicle's reliability and lifespan.

Industrial Machinery:

Industrial machinery, such as pumps, compressors, and conveyor systems, relies on oil seals to prevent contamination and fluid leakage. Oil seal kits ensure that these machines continue to operate smoothly and efficiently.

Agricultural Equipment:

Tractors, harvesters, and other agricultural machinery often work in demanding conditions. Oil seal kits contribute to the proper functioning of these machines, helping farmers maintain productivity.

Heavy Equipment:

Weir Type Diaphragm Valve: A Reliable Solution for Flow Control

Plug Valves: Versatile Flow Control Solutions

The Advantages of Overhead Conveyor Bearings in Industrial Automation

Drum Gear Coupling: The Backbone of Efficient Power Transmission

What is a waste heat recovery boiler and how does it work?

Steel Braided Hydraulic Hose: The Strong and Reliable Solution

Can a 40ft expandable container house be customized?

Construction and mining equipment, characterized by their heavy-duty operations, require reliable sealing to prevent dust and debris from entering critical components. Oil seal kits are an integral part of maintaining these machines' operational efficiency.

Marine and Offshore Equipment:

In maritime and offshore applications, exposure to saltwater and harsh environmental conditions underscores the importance of effective sealing. Oil seal kits ensure that marine engines and equipment remain operational and corrosion-free.

Advantages of Using Oil Seal Kits:

The adoption of oil seal kits brings several advantages to maintenance practices and machinery operations:

Convenience:

Oil seal kits streamline the maintenance process by providing all necessary components in a single package. This convenience saves time and reduces the risk of mistakes during installation.

Reduced Downtime:

Rapid replacement of faulty oil seals using kits minimizes equipment downtime. This is particularly significant in industries where downtime translates to substantial financial losses.

Consistent Performance:

The use of complete oil seal kits ensures that replacement parts are compatible and designed to work together seamlessly. This consistency in performance contributes to the overall efficiency of the machinery.

Expert Design:

Oil seal kits are engineered by experts who understand the complexities of sealing technology. This ensures that the provided components are optimized for their intended applications.

Cost-Effectiveness:

While the initial investment in oil seal kits might seem higher than buying individual components, the long-term cost-effectiveness becomes evident through extended machinery lifespan and reduced maintenance requirements.

Conclusion:

In the intricate world of machinery, where precision and performance are non-negotiable, the role of oil seals and oil seal kits cannot be overstated. These unassuming components act as guardians, protecting valuable machinery from the harmful effects of fluid leaks and contaminants. By using oil seal kits, maintenance becomes more streamlined, efficient, and effective, ultimately contributing to the seamless operation and longevity of mechanical systems across various industries. As technology advances and machinery becomes increasingly complex, the reliance on oil seal kits only grows stronger, highlighting their significance as indispensable tools in the maintenance toolkit of any responsible equipment owner or operator.

Recommended article:Choosing the Right Diesel Engine for Your Vehicle or Equipment

Equal Tee: A Comprehensive Guide to Fittings in Plumbing Systems

Exploring the Function and Benefits of an Equal Tee in Plumbing Systems

Anti Corrosive Primer: Protecting Metal Surfaces From Corrosion

How do hammer union seals work?

What are the differences between expanding gate valves and other types of valves?

What are the common applications of mini ball valves?

Related Articles

-

Natural Gas Y Strainer: Ensuring Optimal Gas Flow and Efficiency

-

Hydraulic Rubber Seal: Ensuring Efficiency and Reliability in Hydraulic Systems

-

Factors to Consider When Choosing a Filter Press Feed Pump

394

0

0

-

What is the difference between rigid and flexible flange coupling?

-

Types of Liquid Tight Non-Metallic Flexible Conduit Fitting

430

0

0

-

Unveiling the Versatility and Importance of O-Rings

384

0

0

-

What is the use of high pressure lined slurry pump?

386

0

0

Comments

0