What is brown aluminum oxide used for?

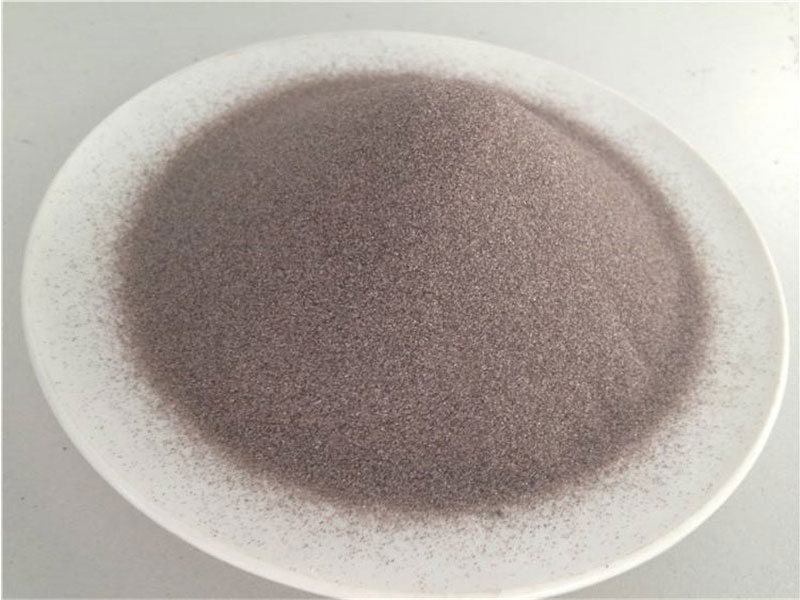

Brown corundum, also known as brown emery, is a versatile industrial material that can be used in a variety of industries and fields. This abrasive has excellent properties that make it ideal for a variety of applications. From surface treatment to manufacturing, brown aluminium oxide plays a vital role in numerous processes. In this article, we will explore the uses and applications of brown aluminium oxide, shedding light on its importance in various industries.

Composition and Characteristics

Before delving into its applications, let's take a look at the composition and characteristics of brown aluminium oxide. This abrasive is produced by melting bauxite at high temperatures in an electric arc furnace. The result is a crystal structure that makes brown aluminium oxide hard and durable.

Key properties of brown aluminium oxide include:

Hardness: brown aluminium oxide is known for its exceptional hardness, making it suitable for abrasive applications.

High melting point: It has a high melting point that allows it to withstand extreme temperatures.

Toughness: Its toughness is a valuable property as it resists breakage and ensures a longer product life.

Grain structure: The abrasive grains have a sharp, angular shape that allows for efficient cutting and grinding.

Chemical Inertness: It is chemically inert and does not react with most materials.

Abrasive strength: Brown Aluminium Oxide has strong abrasive properties for effective material removal.

Applications of Brown Aluminium Oxide

Abrasive Industry:

The most prominent use of brown aluminium oxide is in the abrasive industry. It is widely used in sandblasting, sandpaper, grinding wheels and other abrasive applications. The sharp edges and hardness of the abrasive grains ensure effective material removal and surface finishing. It is commonly used for tasks such as rust removal, paint stripping and surface preparation prior to painting or coating.

Metallurgy:

In the metallurgical industry, brown aluminium oxide plays a role in various applications. It is used to blast metal surfaces to remove rust, oxides and contaminants. It is also used in the manufacture of metal and alloy products where abrasive properties are required to shape and finish parts.

Precision Grinding:

Brown aluminium oxide is an important component in precision grinding applications. Grinding wheels, whetstones and other grinding tools use this abrasive to achieve fine finishes and tight tolerances. It is a key component in the production of cutting tools and precision engineered components.

Coated abrasives:

Brown aluminium oxide is usually coated on paper, cloth or other backings to make sandpaper and abrasive belts. These coated abrasives are widely used in woodworking, metalworking and surface finishing applications. The consistent size and sharp edges of the abrasive particles help to achieve a smooth and uniform surface finish.

Ceramic Industry:

The ceramic industry benefits from brown aluminium oxide in the production of ceramic parts and refractory materials. It is used as a component in ceramic mixtures and contributes to density and wear resistance. The wear resistance of brown alumina makes it a valuable additive in ceramic manufacturing.

Blasting Media:

Brown Aluminium Oxide is used as an effective blasting media in applications such as cleaning and blasting. It can be used to clean and prepare surfaces for blasting or coating. The durability and recyclability of this abrasive makes it an environmentally friendly choice for such applications.

Polishing and Lapping:

In precision machining and optical manufacturing, brown aluminium oxide is used for grinding, polishing and finishing. It is used to achieve high quality surface finishes on lenses, glass and precision components.

Anti-slip surfaces:

Brown aluminium oxide is incorporated into anti-skid surfaces such as road paints and coatings to improve traction and safety. Its hardness and durability ensure a long-lasting anti-skid surface.

Refractory Materials:

The refractory industry utilises brown corundum to produce high-temperature and wear-resistant refractory materials. It is commonly used in the lining of furnaces and kilns, which must withstand extreme heat and wear.

Shot Peening:

In the aerospace and automotive industries, brown alumina is used for shot peening, a process that applies compressive stress to the surface of a component to improve its fatigue life and durability.

Tumbling Media:

Brown aluminium oxide is used as a tumbling media for deburring, finishing and polishing metal and plastic parts. This application is common in industries such as jewellery manufacturing where achieving a high quality surface finish is critical.

Thermal Spraying:

In thermal spray applications, brown aluminium oxide is used as a coating material to provide abrasion resistance and protection to surfaces exposed to harsh environments.

Conclusion

Brown aluminium oxide is a versatile material with a wide range of applications in various industries. Its hardness, toughness and abrasive properties make it an indispensable component of abrasives, manufacturing processes and surface treatments. Whether it is removing rust from metal surfaces, enabling precision grinding, or enhancing the durability of refractory materials, brown alumina plays a pivotal role.

The material's enduring popularity can be attributed to its ability to increase productivity, improve product quality and contribute to safety in a variety of industrial applications. As the industry continues to evolve and demand high-quality materials, brown alumina remains a reliable choice to meet these diverse needs.

Comments

0