How Long Does It Take a SLA 3D Printer to Print a Model

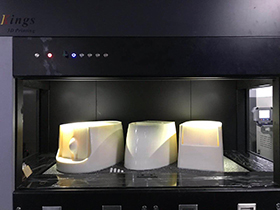

With SLA 3D printing technology getting more and more popular, many are curious about how long it takes for a SLA 3D printer to print a model. The printing time of SLA 3D printer mainly depends on the size of the product (the volume), the layer thickness, model orientation and also machine printing efficiency.

1.The larger the object, the longer it will take. For a small model, it takes maybe only 15 minutes, and it can take a few days to print a large house model.

2.For industrial SLA 3D printer, layer thickness can range from 0.05mm to 0.2mm. In actually practice, to reach better surface quality, layer thickness between 0.05mm and 0.1mm is most widely used. Take a same object for instance, if we choose 0.05mm, printing time will double that of 0.1mm.

3.For a same object printed by SLA 3D printer, with different orientation, printing time will also differ. The taller the total height we oriented, which means more layers and more recoating time, more time will be taken.

4.Different machine software, machine design, also make a big influence in printing time.

How to clean a meat grinder?

How does a turret CNC lathe machine work?

How Long Does It Take for Clothes to Dry in a Drying Machine?

Understanding the Operation of a Pneumatic Chemical Injection Pump

What is a Drilling Rig and Why is it Used?

Powering Progress: Advantages and Applications of Slip Ring Induction Motors

Prolonging Pump Life: When and How to Replace Slurry Pump Parts

Kings 3D, as a leading industrial SLA 3d printer manufacturer in china, has prominent advantage in printing efficiency, thanks to breakthrough in intelligent high speed scanning system (15m/s), enhanced variable laser spot variable power, automatic identifying upskin and downskin with differentiated parameters and different parameter database with different layer thickness.

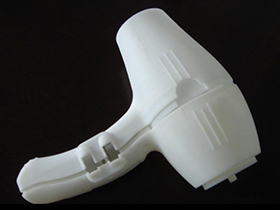

3D printing is a kind of rapid prototyping technology, which is based on a digital model file. A technique for building objects by printing them layer by layer using adhesive materials such as powdered metal or plastic. 3D printing usually ends with a digital data printer, which is often in the mold making, industrial design and other areas to be used in the production of models, and then gradually used in the direct production of some products. The technology is used in jewelry, shoes, industrial design, construction, automobiles, aerospace and medical industries, education, geographic information systems, civil engineering and other fields.

Pipe Rotators That Will Make Your Life Easier

Harnessing the Power of Cleanliness: The 55W UV Sterilizer

Unlocking the Secrets of Radiation Measurement Instruments: How Do They Work?

How Vertical Pressure Steam Sterilizers Keep Healthcare Safe

Demystifying the Cone Crusher Machine: Your Guide to Understanding its Function and Benefits

What are the Benefits of Electrical Actuators?

What is the meaning of ISO tank container?

Related Articles

-

Automatic CNC Machines: Revolutionizing Precision Manufacturing

-

Harnessing the Power of Ozone Generators: A Deep Dive into Applications and Benefits

-

EPE Foam Bonding Machine: Enhancing Foam Processing Efficiency

-

Choosing the Right Battery Capacity for an Electric Wheel Loader in a Construction Project

327

0

0

Comments

0