The Principle and Method of Valve Grinding

Valve grinding is a process used to ensure that the valves of an engine are properly seated within their valve seats. The process involves using a valve grinding machine to grind the valves, which helps to promote efficient engine performance. In this article, we will explore the principles and methods of valve grinding.

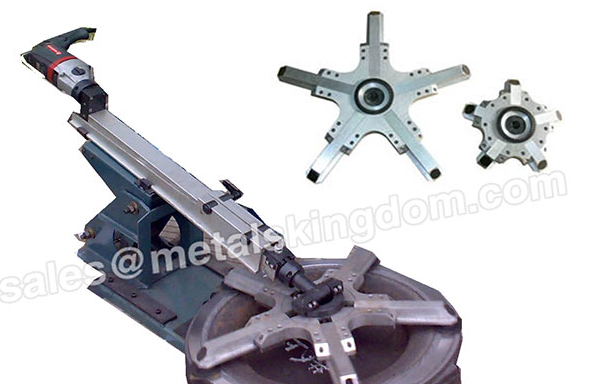

The principle of valve grinding is relatively simple. The valve grinding machine consists of a rotating grinding wheel that grinds the valve as it is held in place by a chuck. The grinding wheel is made of a hard material, typically a ceramic or diamond abrasive, that can grind through the hardened steel of the valve and the valve seat.

To begin the valve grinding process, the valve is first removed from the engine and cleaned to remove any debris or carbon buildup. The valve is then inspected to ensure that it is not warped or damaged in any way. If the valve is found to be damaged, it will need to be replaced.

Once the valve is ready for grinding, it is mounted in the chuck of the valve grinding machine. The grinding wheel is then brought into contact with the valve and the machine is turned on. The valve is then rotated by the machine while the grinding wheel grinds away the hardened steel of the valve and valve seat. This helps to ensure that the valve is ground evenly and is properly seated within its valve seat.

Valve grinding is a precision process that requires careful attention to detail. The grinding wheel must be dressed properly to ensure that it grinds the valve evenly and does not leave any high or low spots on the valve. Additionally, the valve must be rotated by the machine at the correct speed and pressure to ensure that it is ground evenly and properly.

Recommended article:Understanding the Difference Between AWP and EWP

What is the Difference Between AWP and EWP?

Horizontal Flow Wrap Machine: Enhancing Packaging Efficiency and Productivity

Automatic Screw Driving Machine: Efficient and Reliable Automation Solution

Screwdriving Robot: Revolutionizing Industrial Automation

How does oil extraction machines work?

Inline Plastic Scrap Granulator: A Revolutionary Solution for Plastic Waste Recycling

There are several methods that can be used for valve grinding, including manual and automatic methods. Manual valve grinding involves using a hand-held grinding tool to grind the valve and valve seat by hand. This method is time-consuming and requires a great deal of skill and experience to ensure that the valve is ground evenly and properly. It is also less precise than automatic valve grinding.

Automatic valve grinding involves using a valve grinding machine to grind the valve and valve seat automatically. This method is faster and more precise than manual valve grinding and requires less skill and experience. Automatic valve grinding machines are available in a range of sizes and capacities to suit different engine types and sizes.

In conclusion, valve grinding is an important process used to ensure that the valves of an engine are properly seated within their valve seats. The process involves using a valve grinding machine to grind the valves, which promotes efficient engine performance. The principles of valve grinding are relatively simple, but the process requires careful attention to detail to ensure that the valve is ground evenly and properly. There are several methods that can be used for valve grinding, including manual and automatic methods. Automatic valve grinding is faster and more precise than manual valve grinding and requires less skill and experience. If you are an automotive mechanic, investing in a valve grinding machine is a wise decision that can help you provide better service to your customers and improve the efficiency of your business.

X-ray Counter: Revolutionizing Medical Imaging

Enhancing Efficiency and Precision: The Advantages of CNC Pipe Threading Lathes

Understanding the Pricing Factors of Portable Pipe Cutting Machines

What is Colour Coated Steel?

What are the applications of waste heat boilers?

Unlocking Precision and Efficiency: How Fiber Laser Cutting Machines Work

Mushroom Grinding Machine: Revolutionizing the Processing Industry

Related Articles

Comments

0