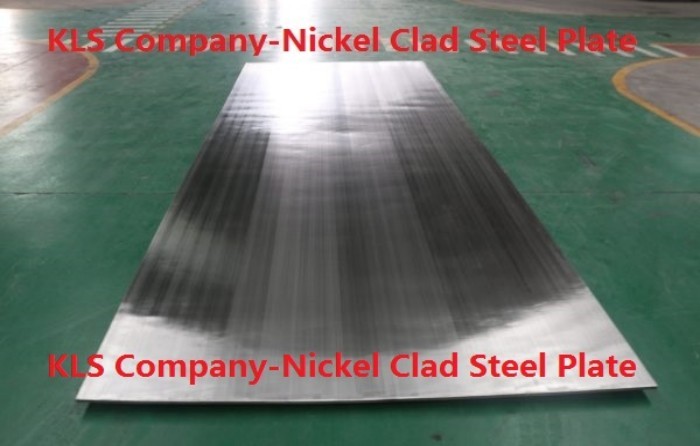

Nickel Clad Steel Plate: A Durable Fusion of Corrosion Resistance and Structural Strength

Introduction: Nickel Clad Steel Plate is a composite material that combines the exceptional corrosion resistance of nickel with the structural strength and durability of steel. This innovative alloy has gained popularity in diverse industries, where a balance between corrosion protection and mechanical integrity is crucial.

Corrosion Resistance: Nickel is renowned for its excellent corrosion resistance properties, making it an ideal choice for applications in aggressive environments. The nickel layer in the Nickel Clad Steel Plate acts as a protective barrier, shielding the underlying steel from corrosive substances, such as acids, alkalis, and seawater. This corrosion resistance ensures prolonged service life, reduced maintenance costs, and enhanced reliability. The clad plate finds applications in industries such as chemical processing, marine engineering, oil and gas, and desalination plants, where exposure to corrosive elements is common.

Structural Strength and Durability: Steel, known for its strength and durability, forms the core material of the Nickel Clad Steel Plate. The steel layer provides exceptional mechanical integrity, enabling the clad plate to withstand high mechanical stresses, pressure differentials, and abrasive conditions. This makes it suitable for applications requiring structural strength, such as pressure vessels, storage tanks, heat exchangers, and pipelines. The fusion of nickel and steel creates a composite material that delivers both corrosion resistance and structural robustness, making it a reliable choice for critical equipment in various industries.

Recommended article:

What is anti-fingerprint stainless steel?

How to Use Water Ripple Stainless Steel Sheets

6 Tips To Get The Most Out of Your Conveyor Belt

What is the difference between uns N07718 and Inconel 625?

What is the difference between Galvalume and galvanized steel?

What are Magnesia alumina brick used for?

Stainless Steel Teppanyaki Plate: Culinary Excellence at Your Fingertips

Versatility and Wide Applications: Nickel Clad Steel Plate offers versatility and finds extensive use across multiple industries. Its corrosion resistance and strength make it ideal for applications in chemical plants, offshore platforms, power generation facilities, and marine structures. The composite material is well-suited for handling corrosive substances like sulfuric acid, hydrochloric acid, and brine. Furthermore, it can withstand high temperatures, making it suitable for applications in the aerospace, automotive, and energy sectors. The wide range of applications demonstrates the adaptability and reliability of Nickel Clad Steel Plate in diverse industrial settings.

Cost-effective Solution: The use of Nickel Clad Steel Plate provides a cost-effective solution for corrosion-resistant applications. By combining nickel and steel, the composite material offers superior performance compared to solid nickel plates, while significantly reducing material costs. The clad plate's design allows for efficient fabrication, with the ability to be welded, cut, and formed like conventional steel. This ease of fabrication translates into cost savings during manufacturing processes. Moreover, the extended service life and reduced maintenance requirements of clad plates contribute to long-term cost-effectiveness for industries seeking durable corrosion-resistant solutions.

Conclusion: Nickel Clad Steel Plate offers a compelling combination of corrosion resistance and structural strength. Its versatility, durability, and cost-effectiveness make it a preferred choice in industries where protection against corrosive substances and mechanical integrity are paramount. As a reliable composite material, Nickel Clad Steel Plate continues to find widespread applications across multiple sectors, ensuring extended equipment lifespan and enhanced performance.

How Does Refining Flux Work?

The Difference Between Dead-Burned Magnesite and Fused Magnesite with Large Crystals

The Most Common Super Alloy and Its Applications

Are glass beads safe for sandblasting?

Things You Should Know About 358 Security Fence

Will Pulverized Coal Explode? Unraveling the Myth and Safety Measures

What is the best Titan spray gun?

Related Articles

-

How durable is PVD coated stainless steel?

279

0

0

-

308

0

0

Comments

0